BUILT FOR INDUSTRY. BACKED BY EXPERIENCE. POWERED BY PURPOSE.

Precision Saws, Inc. delivers purpose-driven solutions for demanding operations. Our sawing machines and automated systems are designed with the aluminum,metal distribution, automotive, and aerospace industries in mind. These systems are not just equipment—they're productivity tools with a clear function: increase throughput, simplify labor, and hold tight tolerances throughout the entire production cycle.

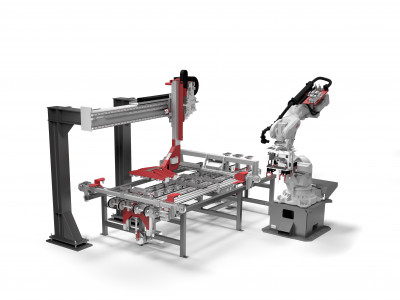

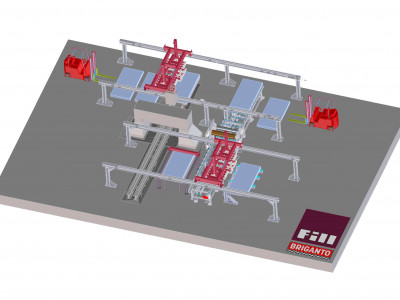

BRIGANTO offers complete sawing and material handling systems that are proven in some of the most demanding environments. Every machine is engineered to cut clean, protect the material, and make life easier for your operators.

System Options for Complex Production Goals

Our sawing machines and automated systems are selected based on your process demands.

- Aluminum Plate Saws

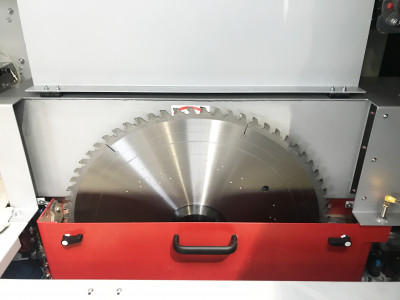

High-capacity machines like the ALU PRECISER bring clean cuts to rolled- and cast plates. With cutting lengths up to 20 feet and motors rated up to 103 horsepower, these machines are built to handle high-volume demands without compromising surface protection or cutting consistency.

| Saw Type | Max. Cutting Height | Cutting Length | HP Saw Motor |

|---|---|---|---|

| Alu Preciser AP15 | 6 inch | 88.5 / 127.5 / 167 inch Custom cutting length upon request. |

48 HP |

| Alu Preciser AP20 | 8 inch | 88.5 / 127.5 / 167 inch Custom cutting length upon request. |

71 HP |

| Alu Preciser AP25 | 10 inch | 88.5 / 127.5 / 167 inch Custom cutting length upon request. |

106 HP |

- Extrusion and Remnant Saws

Systems like the CROSS CUT manage everything from delicate profiles to solid round bars. Positioning accuracy holds at ±0.002 inch, and material is automatically staged, aligned, and clamped without needing profile-specific templates.

| Saw Type | Max. Cutting Length (Layer Width) |

|---|---|

| CC 25/065 | 25.5 inch |

| CC 25/095 | 37.4 inch |

| CC 25/125 | 49.2 inch |

Infeed Length Bar and Stock / Cutting Length:

14 - 28 feet. Custom Infeed / cutting length upon request

HP Saw Motor: 52 HP

- Trim Saws and Mill Systems

For aluminum mill operations, our trim saw and handling systems automate the process from material loading through finished stacking. These systems are built to control flow and reduce manual handling while maintaining tight cutting parameters across varied stock.

Every solution can be expanded. Additional modules include part cleaning, dimensional measuring, laser marking, automated stacking, and more.

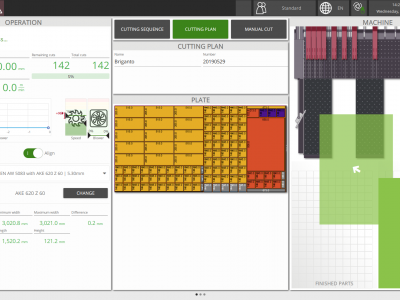

Automation That Understands the Floor

A fully automated system only delivers value when it works with your environment, and these sawing machines are built to do just that. Materials are aligned and measured without manual adjustment. Parameters are pulled from a cutting library that accounts for both the blade and the material. Operator controls are touchscreen-based, walking users through each step with visual cues and logic that makes sense.

Automation is not the goal. Productivity is.

Industries That Rely on This Technology

You’ll find our sawing machines and automated systems in operations focused on:

- Metal distribution centers

- Aluminum extrusion and distribution

- Aerospace component cutting

- Tier I and Tier II automotive manufacturing

- Aluminum plate processing and casting

- Structural fabrication in construction and energy sectors

If your current sawing machine or automated system is slowing you down or compromising quality, this is where we help.

Let’s build the system that works for your brand.

Talk to our team about your space, process, and expectations. Then, we’ll roll up our sleeves and build something that matters.